The salt spray test is a standardized test method used to check corrosion resistance of chrome plated piston rod. It involves a hard chrome bar sample being placed in a chamber containing a fine mist or aerosol of salt particles, representing natural weather conditions. The damage to the sample is measured visually and compared against other samples, with the results being reported as equivalent “hours at” exposure.

Salt spray testing is used to assess the durability of finishes and coatings on hydraulic cylinder rod surfaces. The test can be used to evaluate the impact of different exposure conditions, such as humidity and temperature, on a coating’s ability to resist corrosion. It is also used to compare the performance of different coatings and finishes.

There are three kinds of salt spray test: Neutral Salt Spray Test (NSS), Acetic Acid Salt Spray test (AA SS) and Copper Accelerated Acetic Acid Salt Spray test (CA SS),, among which the most widely used test is neutral NSS.

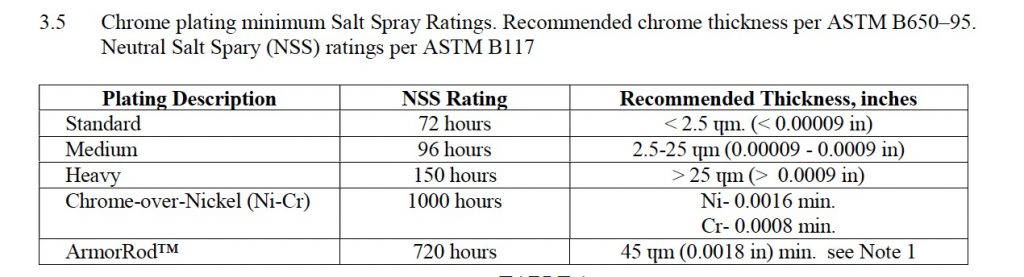

Salt spray testing is usually carried out to most widely used standard ASTM B117 neutral salt spray test for between 24 and 1000 hours, however this may be specified. The testing typically involves using a 5% sodium chloride (NaCl) solution with is atomised within a sealed chamber to create a saltwater mist, accelerating the corrosion of the materials being tested.

As a professional cylinder rod manufacturer, we produce hard chrome plated bar, Nickel-Chrome Plated Rod, Induction hardened chrome rod with all kinds of size and materials like CK45. SAE4140,42CRMO4, DATONG HYDRAULIC also has rich experience in salt spray test to meet customer’s requirement.