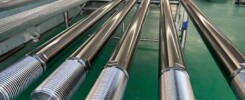

Induction hardened chrome rods are precision-crafted chromium alloys treated with a magnetic induction process. This technology heats the metal surface to extreme temperatures (up to 1,500°C) and rapidly cools it using a quenching medium. The result? A hardened outer layer (5-8mm thick) with exceptional wear resistance, while the core remains ductile for shock absorption.

Key Benefits for Manufacturing Induction Hardened Chrome Rods:

✅ Longer Lifespan: Reduce replacement frequency and labor costs.

✅ Superior Strength: Handle heavy loads and repetitive stress without bending or breaking the raw manterials

✅ Corrosion Resistance: Ideal for automotive, aerospace, and marine industries like hydraulic cylinder applications exposed to harsh environments.

✅ Cost Efficiency: Save up to 40% on maintenance over traditional rods.

The Induction Hardened Chrome Rods Over Other Solutions?

Feature Induction Hardened Chrome Rods Traditional Chrome Plating

Durability 3x longer lifespan Prone to flaking and peeling

Strength High tensile strength (up to 2,500 MPa) Brittle under stress

Corrosion Resistance Passes ASTM B117 salt spray tests Limited resistance to moisture

Temperature Tolerance Up to 800°C Melts at 600°C

Induction hardened chrome rods are indispensable for industries plagued by metal fatigue. Designed for high-stress environments, these rods deliver unmatched durability, corrosion resistance, and strength—making them a must-have for manufacturers worldwide. Order Samples to test our rods risk-free with a 30-day satisfaction guarantee.