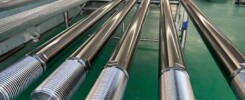

chrome rod for hydraulic cylinder typically made of cold-rolled or hot rolled steel bar and then hard chrome plaing the OD surface. Hydraulic cylinders rely on precision chrome rods to withstand extreme pressure, friction, and environmental stress. So choosing the right chrome rod supplier isn’t just about price—it’s about ensuring your machinery’s longevity, safety, and efficiency.

Our Factory Solution Of Chrome Rod For Hydrauic Cylinder

✅ Cold-Worked Chrome-Moly Alloy: Our rods are forged from SAE 4140/4340 steel with chromium content (1.2-1.8%) for enhanced hardness and fatigue resistance.

✅ Heat Treatment Process: Precise quenching and tempering achieve HRC 58-62 surface hardness, reducing wear by up to 60% compared to standard rods.

✅ Testing Standards: Each rod undergoes 100% non-destructive testing (UT/MT) and pressure fatigue tests at 1.5x design limits

✅ Machining Precision: CNC grinding achieves Ra 0.4-0.8 µm surface roughness (vs. industry average of Ra 1.6 µm).

✅ Polishing Process: Multi-stage honing reduces micro-cracks and ensures uniformity under magnification.

✅ Certifications: Compliance with ASTM B117 salt spray testing (2,000+ hours) and ISO 9227 immersion corrosion standards.

The Description Of DATONG Chrome Rod For Hydraulic Cylinder

Material: CK45, SAE1045, 4140, 4340, 4130,JIS45C, F-1140, 40Cr, 20MnV6, 42CrMo,SAE1518,SAE8620/8630, SS431, SS430, Stainless Steel 304/316/2205, etc.

Type: Chrome Plated Bar/Chrome Plated Rod/Nickel-Chrome Plated Rod/Hollow Chrome Bar/Hollow Bar

Heat Treatment Type: 1) Normal no heat 2)Q+T(Quenched+Tempered) 3)Induction Hardened

Diameter: Φ 6-800mm/Length: max.20 meters

Salt Spray Test: Available As Per Request

Chrome layer: min 20/25/30/50 Micron or customized

Straightness: <= 0.5/1000

Roughness: Ra <= 0.4u

Diameter tolerance: ISO f7/f8/f9/h8/h9 or as request