Product Catalog

- Custom Hydraulic Cylinder

- Honed Tube

- Cold Drawn Seamless Tube

- Ready to Honed Tube

- Chrome Plated Bar

- Hollow Chrome Bar

- Induction Hardened Chrome Rod

- Stainless Steel Cylinder Barrel

- 4140 Hydraulic Cylinder Barrel

- 4140 Hard Chrome Rod

- 4140 Round Steel Bar

- High Pressure Hydraulic Tube

- 34CrMo4 Seamless Steel Tube

Product Detailes:

Name:Cold Drawn Seamless Tube

Place of Origin: China

Brand Name: Datong

Certification: ISO9001:2008

As a professional cold drawn seamless tube manufacturer and supplier,Datong has been supplying and exporting cold drawn seamless tube for almost 20 years.

cold drawn seamless tube widely used in hydraulic system with precision steel tube, hydraulic press with precision steel tube, shipbuilding with steel tube, hydraulic machinery,hydraulic cutting machine, hydraulic equipment, hydraulic tubing, engineering machinery.

Material: ST52,CK45,4140,SCM440,16Mn,42CrMo,E355,Stainless Steel 304/316,Duplex 2205,etc.

Manufacturing Method: Cold Drawn

OD Size : 25mm – 500mm

Wall thickness: 2-50mm

Length: max 16m

Standard: GB/T8713-88, GB/T3639-2009

Packing: Bundle with steel strip and PE sheet or wooden case

Manufacturing Process Of seamless cold drawn steel tube

Cold drawn seamless tube and pipe is produced by piercing hot billets and subsequent rolling which reduces their diameter and elongates them. This material is then passed through a die and over a mandrel plug to produce an accurate size and gauge which is the essence of the cold drawing process.

Benefits Of Cold Drawn Seamless Tube

Higher Strength & Hardness Properties

Size Accuracy

Enhanced Appearance

Uniform Micro-Structure

Easier To Machine

Tight tolerances, resulting in reduced machine time

Possible spiraling eccentricity inherent in product

Our main business range is listed as follows:

Carbon Seamless Steel pipe/tube

Hydraulic cylinder tube(Honed tube)

Hard chrome plated rod/bar/shaft(Piston rod)

Induction Hardened Chrome Plated Bar

Hollow Chrome Plated Bar

1.Petrol,gas,water pipe,construction,fluid pipe,etc

2.Great for high-pressure applications such as HPLC

3.Hydraulic Systems

4.Derivative of all Honed tubes

5.resistant to internal pressure

6.cylinder manufacture

7.hydraulic and pneumatic applications

1.Extensive production experience: more than 20 years manufacturing experience for honed tube and chrome plated rod, in Australia, Thailand, Brazil, India, Iran, Indonesia, South Africa and other countries have long-term buyers.

2.Advanced production equipment: cold drawing machine, honing machine, skiving & roller burnishing machine, straightening machine, polishing machine, heat treatment furnace, grinding machine, etc. We have professional technicians do regular scheduled maintenance on these machines to guarantee them work well.

3.High quality raw material: our raw material mainly from some famous steel mills, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

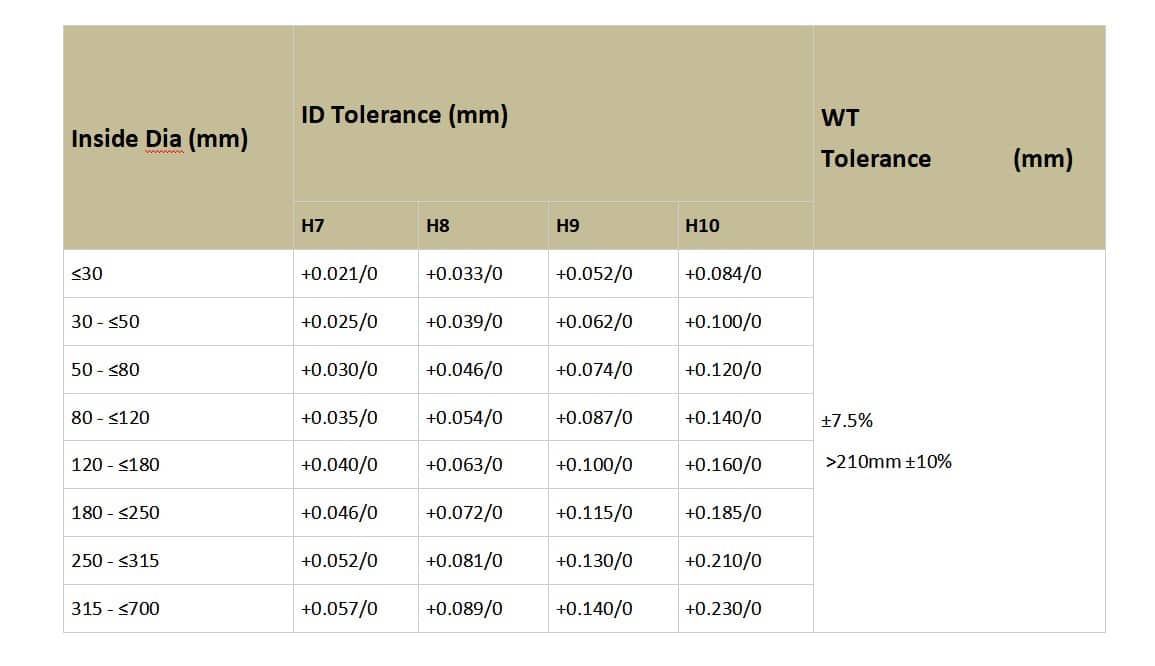

4.High precision: Honed Tube, inside surface roughness 02-0.4 um, straightness max 0.5/1000, strict tolerance DIN2391 H8. Skived & Roller Burnished Tube, inside surface roughness under 0.2 um, straightness max 0.2/1000, strict tolerance DIN2391 H8. Chrome Plated Rod, chrome layer 10 micron to 100 micron, strict tolerance ISO f7.

5.Strict quality control: we have professional in-house QC to inspect all products. We will do Chemical Composition Test, Mechanical Property Test, Dimension Inspect, Roughness Test, Chrome Layer Test and other tests in need before delivery.

6.Safe packing: an-rust oil on tubes and rods before delivery. Plastic caps on both ends to protect tube inside surface. Then be packed with seaworthy package or in wooden case.