Product Detailes:

Name: Construction Vehicle Hydraulic Cylinder

Place of Origin: China

Brand Name: Datong

Certification: ISO9001:2008

Anbao as one of the leading construction vehicle hydraulic cylinder manufacturers and suppliers, We has been supplying and exporting machinery hydraulic cylinder for almost 25 years. Anbao has rich experience designing telescopic for a number of industries and applications and can work with you to design a single acting or a double acting design.

Construction vehicle hydraulic cylinders cover various types of vehicles industries and construction applications. Our experienced engineering team helps you work through design considerations to ensure your cylinder meets your requirements. Choose from the following custom telescopic cylinder design options:

- excavator hydraulic cylinders

- dump trucks cylinders

- tractor hydraulic cylinders

- mobile crane hydraulic cylinder

- mining machine cylinders and so on

Excavator hydraulic cylinder is divided into boom cylinder, arm cylinder and bucket cylinder. We can provide you with most well-known brands of excavator cylinders and accessories. We provide rebuilt excavator hydraulic cylinders for Komatsu and Caterpillar excavators to customers worldwide.

Materials and Technology | ||||

Cylinder Barrel/Tube | 1. Material: E355 ST52, CK45, 4140, 42CrMo4, 16Mn(Q345B), ,Stainless Steel 304/316,etc 2. Technology: Seamless, Cold Drawn ,Hot Rolled,Cold Rolled, Forged 3. Surface Roughness: Ra 0.2-0.4μm 4. Choose by different working condition and requirements. | |||

Piston Rod | 1. Material: CK45, SAE1045, 4140, 4340, JIS45C, 40Cr, 20MnV6, 42CrMo, SS431, SS430, Stainless Steel 304/316/ 2. Chrome layer: min 20/25/30/50 Micron or customized 3. Diameter tolerance: ISO f7/f8/f9/h8/h9 or as request 4. Surface treatment: chrome plated, nickel-chromium plated, Q+T, Induction hardened | |||

Seal kits | 1. Hallite, NOK, SKF, Parker, Hercules,Trelleborg,China made,Taiwan made 2. Choose by different working condition and requirements. | |||

As a professional hydraulic cylinder manufacturer, We provide a full-service package from hydraulic cylinder design to on-time delivery, supported by outstanding customer service. Capabilities of our custom cylinders are as follows:

– Cylinder bore diameter: Customized as per client’s request.

– Cylinder rod diameter: Customized as per client’s request.

– Cylinder stroke length: Customized as per client’s request.

– Operating pressure: Customized as per client’s request.

– Hydraulic rod options: Chrome plated, nickel plated, induction hardened, stainless steel rod.

– Mounting options: Essentially any custom flanges your application might need.

– Hydraulic cylinder seals: Seals are made up to the cylinder specs, depending on the cycle usage.

– Cylinder integrations: Check pilot valves, counterbalance valves, solenoid controls, etc.

– Cylinder cushions: Fixed and adjustable cushions, rod and welded sides cushions.

– Paint & finish: Standard, automobile, high temperature options for paint of any color.

– Packaging: From cardboard, boxes, bubble wrap to custom logo & engraving option.

WE ALSO PRODUCE:

Hollow Chrome Bar/ Hollow Bar/Hollow Piston Rod

Hardboard sleeve protection for each bar Wooden case+ steel belt

1.Extensive production experience: more than 20 years manufacturing experience for honed tube and chrome plated rod, in Australia, Thailand, Brazil, India, Iran, Indonesia, South Africa and other countries have long-term buyers.

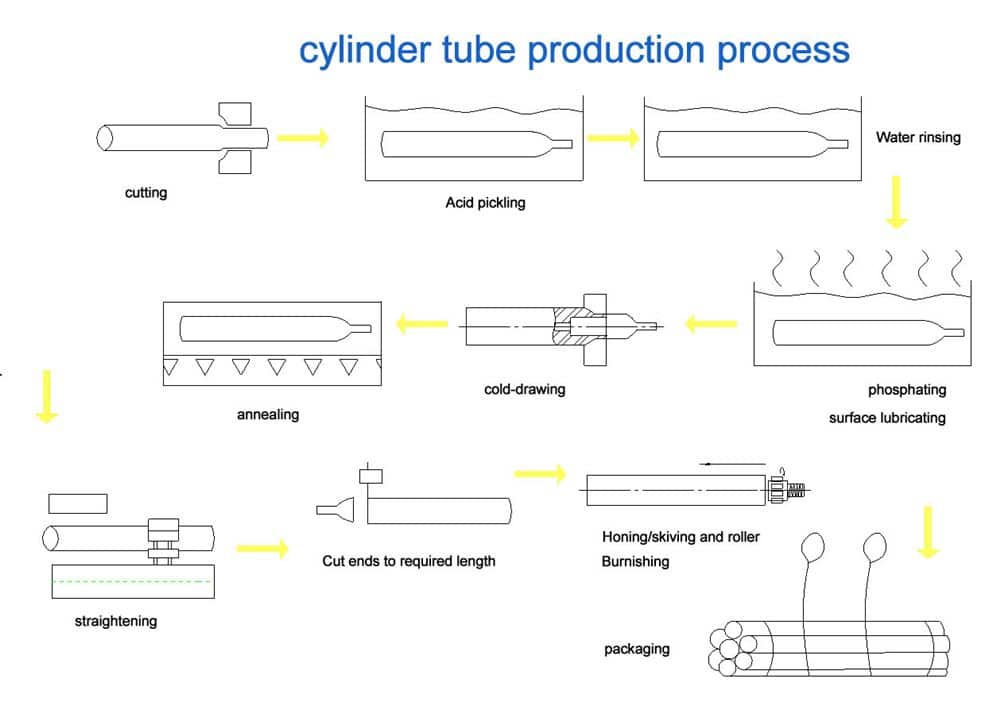

2.Advanced production equipment: cold drawing machine, honing machine, skiving & roller burnishing machine, straightening machine, polishing machine, heat treatment furnace, grinding machine, etc. We have professional technicians do regular scheduled maintenance on these machines to guarantee them work well.

3.High quality raw material: our raw material mainly from some famous steel mills, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

4.High precision: Honed Tube, inside surface roughness 02-0.4 um, straightness max 0.5/1000, strict tolerance DIN2391 H8. Skived & Roller Burnished Tube, inside surface roughness under 0.2 um, straightness max 0.2/1000, strict tolerance DIN2391 H8. Chrome Plated Rod, chrome layer 10 micron to 100 micron, strict tolerance ISO f7.

5.Strict quality control: we have professional in-house QC to inspect all products. We will do Chemical Composition Test, Mechanical Property Test, Dimension Inspect, Roughness Test, Chrome Layer Test and other tests in need before delivery.

6.Safe packing: an-rust oil on tubes and rods before delivery. Plastic caps on both ends to protect tube inside surface. Then be packed with seaworthy package or in wooden case.