Product Detailes:

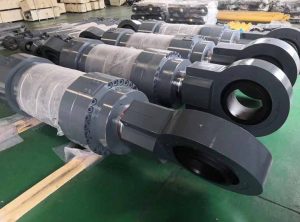

Name:Hydraulic Cylinder

Place of Origin: China

Brand Name: Datong

Certification: ISO9001:2008

As a professional hydraulic cylinder manufacturer and supplier,Datong has been supplying and exporting hydraulic for almost 20 years.

Hydraulic cylinder widely used in hydraulic system with hydraulic machinery,hydraulic cutting machine, hydraulic equipment, hydraulic tubing, engineering machinery.

Liner material: copper (prolongs the life cycle of cylinder)

Inside Cylinder Tube Dia.: 40 – 1000 mm (1.5 – 40 inch)

Stroke :50mm—16000mm

Design Pressure: Max 700 bar (10150 PSI)

Seals Type: PARKER (USA), MERKEL (Germany) or NOK (Japan)

Bearings: LONGXI (China) or SKF

Certificate: DNV, ABS, Lloyds, BV, GL, KR, NK, RINA, RS and CCS

Tolerance EXT: DIN2391, EN10305, GB/T 1619

Application: offshore oil & gas engineering, construction machinery (excavator loader Crane/ snowplow/sanitation vehicle), agricultural machinery, hydraulic engineering, heavy machinery

Packing: Wooden case

we can make a design according to customer’s requirements.If you require our engineer to make a design,please advise us the following specification:

1. Rated pressure

2. Working pressure

3. Test pressure

4. Working condition and environment ,for example ,temperature ,working frequency

5. Pulling force ,and return stroke force

6. Pulling and return speed

7. Assembly size

8. Seal ring requirements .For example , brand ,seal material etc .

9. Tube and piston rod raw material requirements

10. Piston rod surface treatment requirements, for example chroming film thickness,Surface hardness etc .

11. Painting and other spare parts requirements.

WE ALSO PRODUCE:

1.Extensive production experience: more than 20 years manufacturing experience for honed tube and chrome plated rod, in Australia, Thailand, Brazil, India, Iran, Indonesia, South Africa and other countries have long-term buyers.

2.Advanced production equipment: cold drawing machine, honing machine, skiving & roller burnishing machine, straightening machine, polishing machine, heat treatment furnace, grinding machine, etc. We have professional technicians do regular scheduled maintenance on these machines to guarantee them work well.

3.High quality raw material: our raw material mainly from some famous steel mills, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

4.High precision: Honed Tube, inside surface roughness 02-0.4 um, straightness max 0.5/1000, strict tolerance DIN2391 H8. Skived & Roller Burnished Tube, inside surface roughness under 0.2 um, straightness max 0.2/1000, strict tolerance DIN2391 H8. Chrome Plated Rod, chrome layer 10 micron to 100 micron, strict tolerance ISO f7.

5.Strict quality control: we have professional in-house QC to inspect all products. We will do Chemical Composition Test, Mechanical Property Test, Dimension Inspect, Roughness Test, Chrome Layer Test and other tests in need before delivery.

6.Safe packing: an-rust oil on tubes and rods before delivery. Plastic caps on both ends to protect tube inside surface. Then be packed with seaworthy package or in wooden case.