4140 hot rolled steel round bar is a medium carbon alloy steel with good fatigue and impact resistance after heat treating. 4140 hot rolled steel has many applications, including drill collars, chain pins, bolts and sprockets.4140 HRA is a chromium-molybdenun alloy steel that can be oil hardened to relatively high hard enability. The chromium content provides good hardness penetration, and the molybdenum imparts uniformity of hardness and high strength. Through variations in the method of heat treating 4140, an exceptionally wide range of properties can be attained. Other desirable properties include good wear resistance, excellent toughness and good ductility in the quenched and tempered condition. 4140 can attain high mechanical properties (260,000 psi tensile and 235,000 psi yield) in the hardened condition of 500 Brinell.

APPLICATIONS

Typical applications for this grade include drill collars, pins, axles, bolts, and shafts.

4140 Chemical Properties

WE ALSO PRODUCE:

Skived Roller Burnished Tube;

Large size honed bore tube;

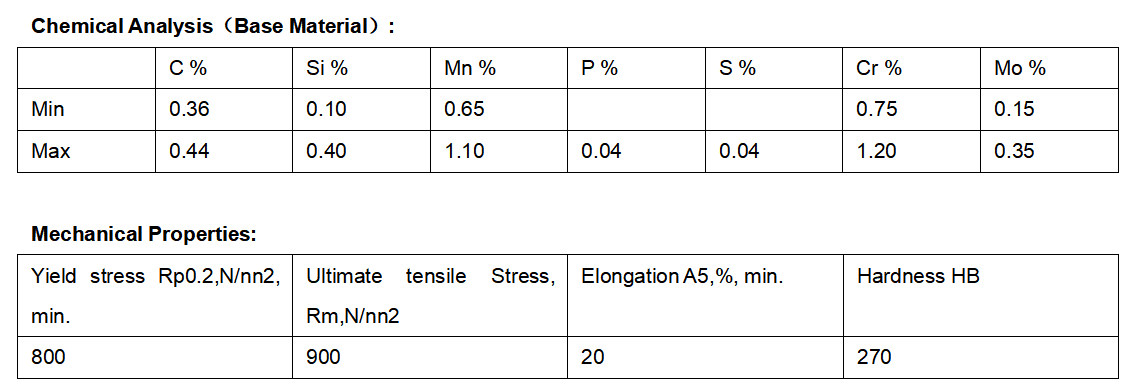

Carbon | 0.36-0.44 |

Manganese | 0.65-1.00 |

Phosphorus, Max % | 0.040 |

Sulfur, Max % | 0.040 |

Silicon | 0.10-0.40 |

Chromium | 0.75-1.20 |

Molybdenum | 0.15-0.35 |

4140 Mechanical Properties (Annealed)

Tensile Strength | 90,000-100,000 ksi |

Yield Strength | 60,000-70,000 ksi |

Elongation in 2″ | 20-30% |

Reduction of Area | 50-60% |

Brinelle Hardness | 185-210 |

4140 Mechanical Properties (Heat Treated)

Tensile Strength | 130,000 ksi |

Yield Strength | 110,000 ksi |

Elongation in 2″ | 16% |

Reduction of Area | 50% |

1.Extensive production experience: more than 20 years manufacturing experience for honed tube and chrome plated rod, in Australia, Thailand, Brazil, India, Iran, Indonesia, South Africa and other countries have long-term buyers.

2.Advanced production equipment: cold drawing machine, honing machine, skiving & roller burnishing machine, straightening machine, polishing machine, heat treatment furnace, grinding machine, etc. We have professional technicians do regular scheduled maintenance on these machines to guarantee them work well.

3.High quality raw material: our raw material mainly from some famous steel mills, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

4.High precision: Honed Tube, inside surface roughness 02-0.4 um, straightness max 0.5/1000, strict tolerance DIN2391 H8. Skived & Roller Burnished Tube, inside surface roughness under 0.2 um, straightness max 0.2/1000, strict tolerance DIN2391 H8. Chrome Plated Rod, chrome layer 10 micron to 100 micron, strict tolerance ISO f7.

5.Strict quality control: we have professional in-house QC to inspect all products. We will do Chemical Composition Test, Mechanical Property Test, Dimension Inspect, Roughness Test, Chrome Layer Test and other tests in need before delivery.

6.Safe packing: an-rust oil on tubes and rods before delivery. Plastic caps on both ends to protect tube inside surface. Then be packed with seaworthy package or in wooden case.